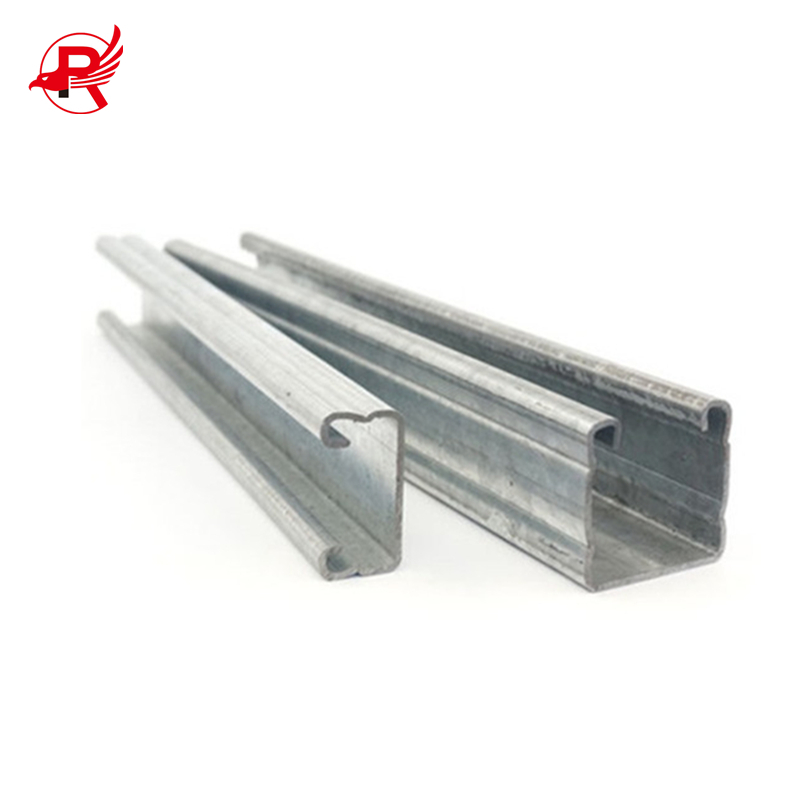

Q345 سوغۇق دومىلىتىلغان گالۋانلاشتۇرۇلغان C قاناللىق پولات ئىشلەپچىقىرىدۇ

C قانال پولاتيۇقىرى كۈچلۈك پولات تاختىدىن ياسالغان، ئاندىن سوغۇق ئېگىلىپ، دومىلىتىلغان يېڭى تىپتىكى پولات. ئەنئەنىۋى ئىسسىق دومىلىتىلغان پولات بىلەن سېلىشتۇرغاندا، ئوخشاش كۈچلۈكلۈك ماتېرىيالنىڭ %30 نى تېجەپ قالالايدۇ. ئۇنى ياسىغاندا، بېرىلگەن C شەكىللىك پولات چوڭلۇقى ئىشلىتىلىدۇ. C شەكىللىك پولات. شەكىللەندۈرۈش ماشىنىسى ئاپتوماتىك بىر تەرەپ قىلىدۇ ۋە شەكىل بېرىدۇ.

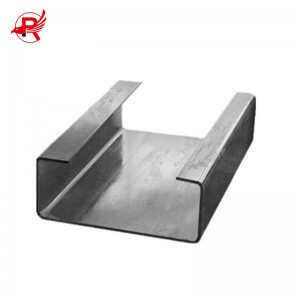

ئادەتتىكى U شەكىللىك پولات بىلەن سېلىشتۇرغاندا، گالۋاڭلاشتۇرۇلغان C شەكىللىك پولاتنى ماتېرىيالىنى ئۆزگەرتمەي ئۇزۇن ۋاقىت ساقلىغىلى بولۇپلا قالماي، يەنە نىسبەتەن كۈچلۈك چىرىشكە قارشى تۇرۇش ئىقتىدارىغا ئىگە، شۇنداقلا ئۇنىڭ ئېغىرلىقى قوشۇمچە پولاتتىن سەل ئېغىرراق.PFC قانىلىئۇنىڭ يەنە تەكشى سىنىك قەۋىتى، سىلىق يۈزى، كۈچلۈك يېپىشتۇرۇشچانلىقى ۋە يۇقىرى ئۆلچەملىك توغرىلىقى بار. بارلىق يۈزلەر سىنىك قەۋىتى بىلەن قاپلانغان بولۇپ، يۈزىدىكى سىنىك مىقدارى ئادەتتە 120-275g/㎡ بولۇپ، بۇنى ئىنتايىن قوغداش كۈچى دېيىشكە بولىدۇ.

ئالاھىدىلىكلەر

1. چىداملىق ۋە چىداملىق: شەھەر رايونلىرىدا ياكى دېڭىز بويى رايونلىرىدا، ئۆلچەملىك قىزىق چىلانغان گالۋاڭلاشتۇرۇلغان داتلىشىشقا قارشى قەۋەتنى 20 يىل ئىشلىتىشكە بولىدۇ؛ شەھەر ئەتراپى رايونلىرىدا 50 يىلدىن ئارتۇق ئىشلىتىشكە بولىدۇ.

2. ئومۇميۈزلۈك قوغداش: ھەر بىر قىسىمنى گالۋاڭلاشتۇرۇشقا بولىدۇ ۋە تولۇق قوغداشقا بولىدۇ.

3. قاپلىمىنىڭ چىدامچانلىقى كۈچلۈك: توشۇش ۋە ئىشلىتىش جەريانىدا مېخانىكىلىق بۇزۇلۇشلارغا بەرداشلىق بېرەلەيدۇ.

4. ياخشى ئىشەنچلىكلىك.

5. ۋاقىت ۋە كۈچنى تېجەڭ: گالۋانلاشتۇرۇش جەريانى باشقا قاپلاش قۇرۇلۇش ئۇسۇللىرىغا قارىغاندا تېز بولۇپ، قۇرۇلۇش ئورنىتىلغاندىن كېيىن قۇرۇلۇش مەيدانىدا رەڭ بېرىشكە كېتىدىغان ۋاقىتنىڭ ئالدىنى ئالالايدۇ.

6. تۆۋەن باھا: گالۋانىزاسىيە قىلىش رەڭ بېرىشتىن قىممەت دېيىلىدۇ، ئەمما ئۇزۇن مۇددەتتە گالۋانىزاسىيە قىلىشنىڭ تەننەرخى يەنىلا تۆۋەن بولىدۇ، چۈنكى گالۋانىزاسىيە چىداملىق ۋە چىداملىق.

قوللىنىش

C تىپلىق پولات پولات قۇرۇلما قۇرۇلۇشىنىڭ تۈۋرۈكلىرى، تام تۈۋرۈكلىرىدە كەڭ قوللىنىلىدۇ، يېنىك ئۆگزە تۈۋرۈكى، تىرناق ۋە باشقا قۇرۇلۇش زاپچاسلىرىغا بىرلەشتۈرۈلىدۇ، بۇنىڭدىن باشقا، مېخانىكىلىق يېنىك سانائەت ئىشلەپچىقىرىش تۈۋرۈكلىرى، تۈۋرۈكلىرى ۋە قوللىرىدىمۇ ئىشلىتىلىدۇ. ئۇ پولات قۇرۇلما زاۋۇتى ۋە پولات قۇرۇلما قۇرۇلۇشىدا كەڭ قوللىنىلىدۇ، ھەمدە كۆپ ئىشلىتىلىدىغان قۇرۇلۇش پولاتلىرى قاتارىدىن. ئۇ ئىسسىق چاقماق تاختىنى سوغۇق ئېگىش ئارقىلىق ياسىلىدۇ. C تىپلىق پولات نېپىز تاملىق، يېنىك، كېسىشمە يۈزى ئەلا ۋە يۇقىرى چىدامچانلىققا ئىگە. ئەنئەنىۋى قانال پولات بىلەن سېلىشتۇرغاندا، ئوخشاش چىدامچانلىق ماتېرىيالنىڭ %30 نى تېجەيدۇ.

C شەكىللىك پولات ئادەتتە ئۆي قۇرۇلۇشىدا ئىشلىتىلىدۇ، يەنى قۇرۇلۇش ماتېرىيالى سۈپىتىدە ئىشلىتىلگەندە ئەۋزەللىكلەرگە ئىگە. ئۇ پەقەت چىداملىق بولۇپلا قالماي، يەنە مۇقىم. ئىلگىرىكى ئاليۇمىن قېتىشمىسى بىلەن سېلىشتۇرغاندا، ئوخشاش قوللىنىش شارائىتىدا، C شەكىللىك پولات ئادەتتىكى شەكىل، ئاز سەرپىيات ۋە ياخشى مۇھىت ئاسراش ئەۋزەللىكلىرىگە ئىگە، ھەمدە ئۇنى يېنىك ئۆگزە تۈۋرۈكى، تىرەك ۋە باشقا قۇرۇلۇش زاپچاسلىرىغا بىرلەشتۈرۈپ، ھەر خىل قوللىنىش ئېھتىياجىنى قاندۇرغىلى بولىدۇ.

C شەكىللىك پولاتنى پىششىقلاپ ئىشلەشنى ئاسانلاشتۇرۇش ئۈچۈن، ئالاھىدە C شەكىللىك پولات ياساش ماشىنىسى ئىجاد قىلىندى، بۇ ماشىنا خېرىدارلارنىڭ تەلىپىگە ئاساسەن ھەر خىل C شەكىللىك پولاتنى ئاپتوماتىك پىششىقلاپ ئىشلەشنى تاماملىيالايدۇ. ئەلۋەتتە، C شەكىللىك پولاتنىڭ تەرەققىي قىلىشىغا ئەگىشىپ، ئۇنىڭ ئىشلىتىلىش دائىرىسى بۇنىڭدىنمۇ كۆپ بولۇپ، ئۇ بارلىق كەسىپلەرنىڭ ھەممە ساھەلىرىدە ئۇچرايدۇ.

پارامېتىرلار

| مەھسۇلات نامى | Cقانال |

| دەرىجە | Q235B، SS400، ST37، SS41، A36 قاتارلىقلار |

| تىپى | GB ئۆلچىمى، ياۋروپا ئۆلچىمى |

| ئۇزۇنلۇقى | ئۆلچەملىك 6 مېتىر ۋە 12 مېتىر ياكى خېرىدارنىڭ تەلىپى بويىچە |

| تېخنىكا | قىزىق دومىلىتىلغان |

| قوللىنىش | ھەر خىل قۇرۇلۇش قۇرۇلمىلىرى، كۆۋرۈكلەر، ئاپتوموبىللار، تىرەش ئۈسكۈنىلىرى، ماشىنا-ئۈسكۈنىلەر قاتارلىقلاردا كەڭ قوللىنىلىدۇ. |

| تۆلەم مۇددىتى | L/C، T/T ياكى Western Union |

تەپسىلاتلار

زاۋۇتتىن چىقىشتىن بۇرۇن C شەكىللىك پولات ساقلىغۇچى ماددىلار ياكى باشقا ئېلېكترو قاپلانغان ئورالمىلارنى ئىشلىتىش سانلىق مەلۇماتلارنىڭ چىرىشىنىڭ ئالدىنى ئېلىشتىكى مۇھىم تەدبىر. توشۇش، قاچىلاش ۋە چۈشۈرۈش جەريانىدا ساقلىنىشى، بۇزۇلماسلىقى ۋە سانلىق مەلۇماتلارنىڭ ساقلاش مۇددىتىنى ئۇزارتىشى كېرەك.

4. ئامبارنى پاكىز تۇتۇڭ ۋە سانلىق مەلۇماتلارنى ساقلاشنى كۈچەيتىڭ.

(1) سانلىق مەلۇماتلارنى ساقلاشتىن بۇرۇن، يامغۇر ياكى باشقا نەرسىلەرنىڭ كىرىشىنىڭ ئالدىنى ئېلىشقا دىققەت قىلىش كېرەك. ھۆل ياكى بۇلغانغان سانلىق مەلۇماتلارنى ئۇلارنىڭ خاراكتېرىگە ئاساسەن يۇقىرى قاتتىقلىقتىكى سىم چوتكا ۋە تۆۋەن قاتتىقلىقتىكى پاختا رەخت قاتارلىق ھەر خىل ئۇسۇللار بىلەن سۈرتۈش كېرەك.

(2) سانلىق مەلۇماتلار ساقلانغاندىن كېيىن، ئۇنى دائىم تەكشۈرۈپ تۇرۇڭ. ئەگەر دات بولسا، دات قەۋىتىنى ئېلىۋېتىڭ.

(3) C تىپلىق پولاتنىڭ سىرتقى كۆرۈنۈشى تازىلىنىپ بولغاندىن كېيىن، ماي سۈرتۈشنىڭ ھاجىتى يوق، ئەمما تاختايلار، نېپىز تاملىق تۇرۇبالار ۋە قېتىشما پولات تۇرۇبالارنىڭ ئىچكى ۋە تاشقى يۈزى داتنى چىقىرىۋەتكەندىن كېيىن داتقا قارشى ماي بىلەن سۈرتۈلۈپ، ئاندىن ساقلىنىدۇ.

(4) ئېغىر دەرىجىدە داتلىشىپ كەتكەن C شەكىللىك پولاتنى داتنى چىقىرىۋەتكەندىن كېيىن ئۇزۇن ساقلىماسلىق كېرەك. ئامبارغا قويۇشتىن بۇرۇن C شەكىللىك پولاتنى ئىشلىتىپ، سىرتقى كۆرۈنۈش سۈپىتىنى تەكشۈرگەندە تۆۋەندىكى ئىشلارغا دىققەت قىلىش كېرەك.

قاتناش:تېز يەتكۈزۈش (ئۈلگە يەتكۈزۈش)، ھاۋا، تۆمۈر يول، قۇرۇقلۇق، دېڭىز توشۇش (FCL ياكى LCL ياكى توپ يەتكۈزۈش)

س: ئۇ ئىشلەپچىقارغۇچىمۇ؟

A: شۇنداق، بىز ئىشلەپچىقارغۇچى. بىزنىڭ جۇڭگونىڭ تيەنجىن شەھىرىدە ئۆزىمىزنىڭ زاۋۇتىمىز بار.

س: سىناق بۇيرۇقىنى پەقەت بىر نەچچە توننالا قىلالامدىم؟

A: ئەلۋەتتە. بىز LCL مۇلازىمىتى بىلەن سىزگە يۈكلەرنى ئەۋەتەلەيمىز. (كونتېينېر يۈكى ئاز)

س: ئەگەر ئۈلگە ھەقسىز بولسا؟

A: ئۈلگە ھەقسىز، لېكىن سېتىۋالغۇچى يۈك توشۇش ھەققىنى تۆلەيدۇ.

س: سىز ئالتۇن تەمىنلىگۈچىمۇ ۋە سودا كاپالىتى بېرىسىز؟

A: بىز يەتتە يىل ئالتۇن تەمىنلىگۈچىسى بولۇپ، سودا كاپالىتىنى قوبۇل قىلىمىز.